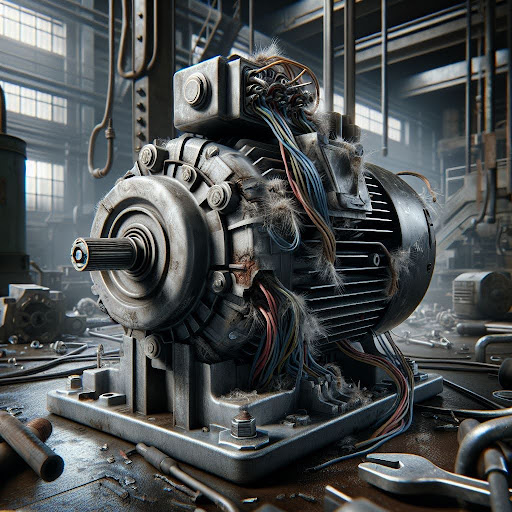

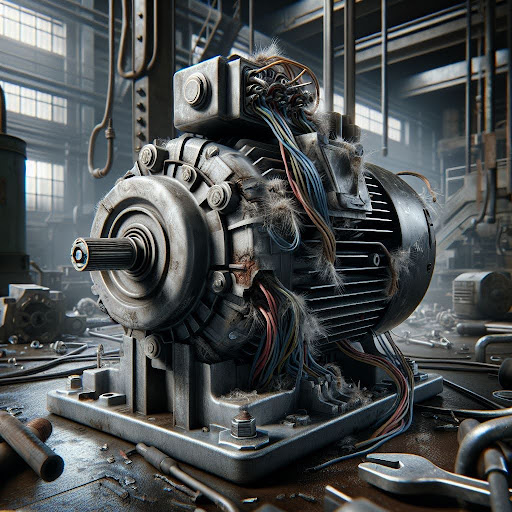

Bearing degradation can cause costly motor and mechanical failures. InsiteAI detects early signs of bearing wear, allowing maintenance teams to plan repairs proactively.

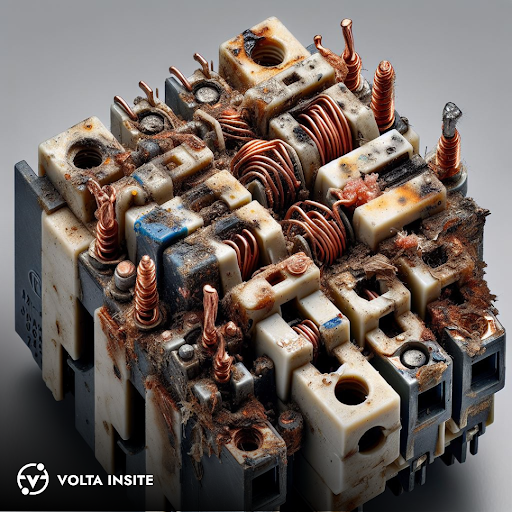

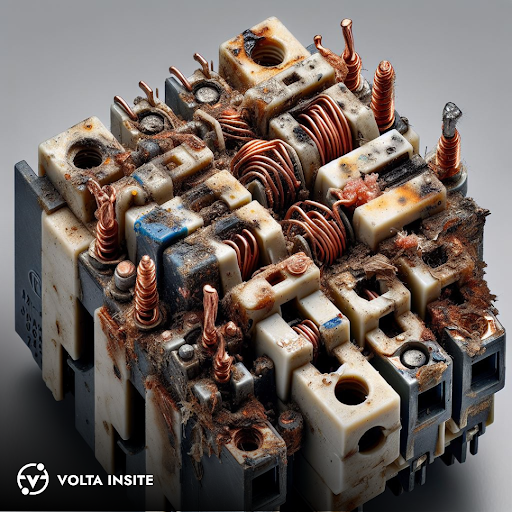

A degrading contactor can cause poor electrical connections and arc flash events. InsiteAI monitors contactor performance, detecting degradation trends before complete failure occurs.

Uneven current across phases signals potential wiring issues or motor degradation. Our system tracks and alerts for current imbalance, improving system performance.

High levels of current distortion can damage sensitive equipment. Our solutions monitor current THD and trend overtime, allowing you to take corrective action to protect critical assets.

Ground faults can cause dangerous conditions and equipment damage. InsiteAI continuously monitors for ground faults, helping protect systems and ensure safe operations.

Excessive motor starts can shorten motor life and increase the risk of failure. InsiteAI detects when motors exceed recommended start limits, helping prevent damage and extend system reliability.

A rise in fault events often signals underlying system issues. InsiteAI tracks event frequency trends, helping identify and resolve root causes before escalation.

Intermittent ground faults can be hard to detect but pose serious risks. Our platform identifies these fleeting events, providing actionable insights to prevent damage.

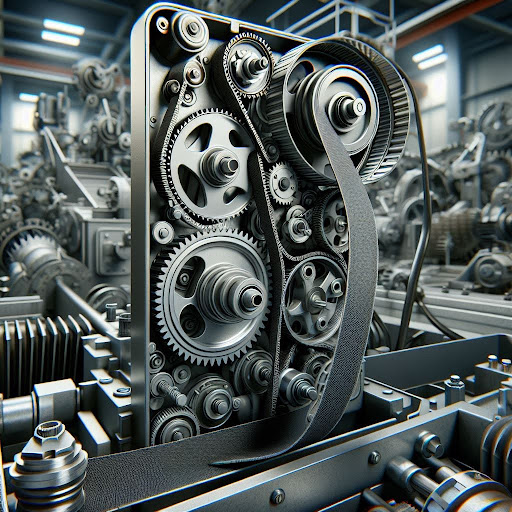

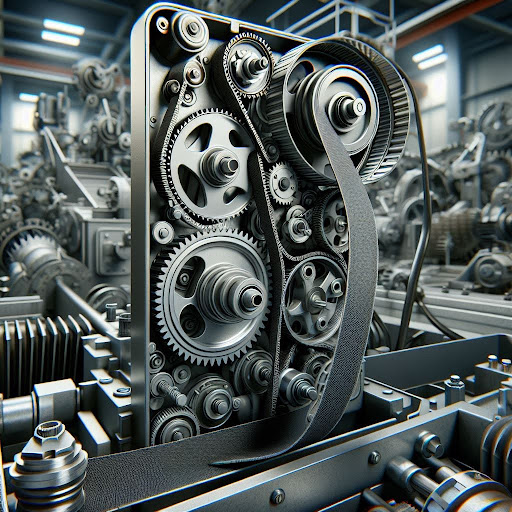

A loose belt can cause slippage, reduced performance, and premature wear. Our system identifies belt loosening early, allowing maintenance teams to address the issue before it impacts operations.

Overcurrent can cause overheating and equipment failure. InsiteAI detects overcurrent conditions promptly, enabling fast corrective actions to prevent major damage.

Loss of a phase in a three-phase system can lead to significant operational failures. Our monitoring system identifies phase loss events in real time, reducing downtime and equipment stress.

Unexpected power drops can disrupt operations. InsiteAI detects drops instantly, providing insight into causes and supporting quicker corrective responses.

Rotor bar defects in motors reduce performance and cause slip and even catastrophic failures. InsiteAI analyzes motor signals to detect early signs of rotor bar issues, protecting key equipment.

Under voltage can reduce equipment efficiency and lead to operational failures. InsiteAI provides real-time alerts when voltage drops below safe thresholds.

Fluctuations in utility power quality can impact overall system reliability. InsiteAI continuously monitors incoming power, alerting when quality dips below acceptable levels.

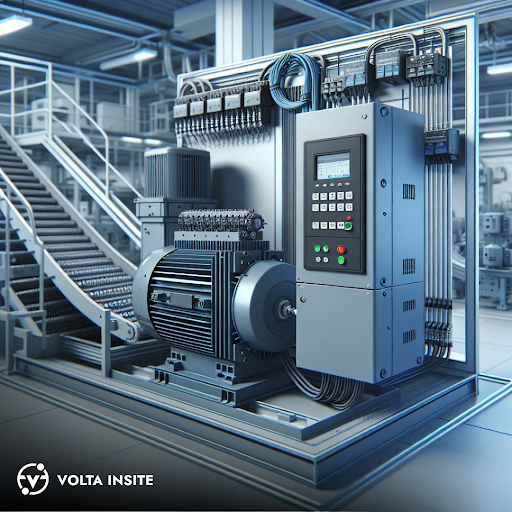

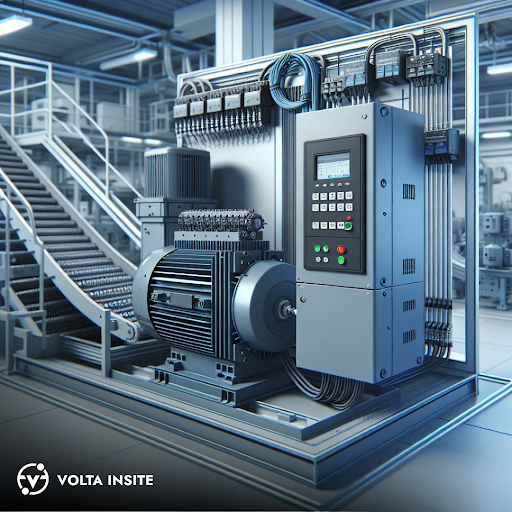

Variable Frequency Drives (VFDs) are essential for controlling motor speed. Our monitoring identifies common VFD faults early, minimizing disruptions to operations.

Unbalanced voltage can overheat motors and shorten their lifespan. InsiteAI monitors voltage across all phases, alerting teams when imbalances arise.

Voltage harmonic distortion impacts the quality of power delivered to equipment. InsiteAI identifies when voltage THD exceeds acceptable limits, reducing the risk of system inefficiencies or damage.