How to Optimize Energy Usage at Oil & Gas Facilities

06/08/2025

06/08/2025

Back to Articles

Back to Articles

Energy consumption represents one of the most significant operating costs for oil and gas facilities. These sites rely on complex machinery, often operating around the clock in challenging environments, which makes energy efficiency a critical factor not only for cost control but also for operational reliability and environmental responsibility. Optimizing energy usage requires a strategic approach that goes beyond simple energy-saving measures—focusing on maintaining power quality and applying effective energy management techniques.

The Importance of Power Quality

Power quality is the measure of how stable and clean the electrical supply is for your facility’s equipment. Poor power quality—manifesting as voltage sags, surges, harmonics, and electrical noise—can severely disrupt operations. For oil and gas facilities, which use sensitive instrumentation and heavy-duty motors, power quality issues can lead to equipment running inefficiently or even failing unexpectedly.

When power is unstable, motors consume more energy to maintain output, sensors deliver inaccurate data, and electrical components are subjected to premature wear. This not only increases energy bills but also risks costly downtime and repairs. By ensuring power quality remains within optimal parameters, oil and gas operators can reduce energy waste, improve safety, and extend the lifespan of critical assets.

Effective Energy Management Strategies

#1: Real-Time Energy Monitoring

Modern oil and gas facilities generate massive amounts of data. Using advanced energy monitoring systems allows operators to track energy consumption continuously across all systems and identify areas of inefficiency or abnormal usage quickly. Early detection helps prevent energy losses before they become costly problems.

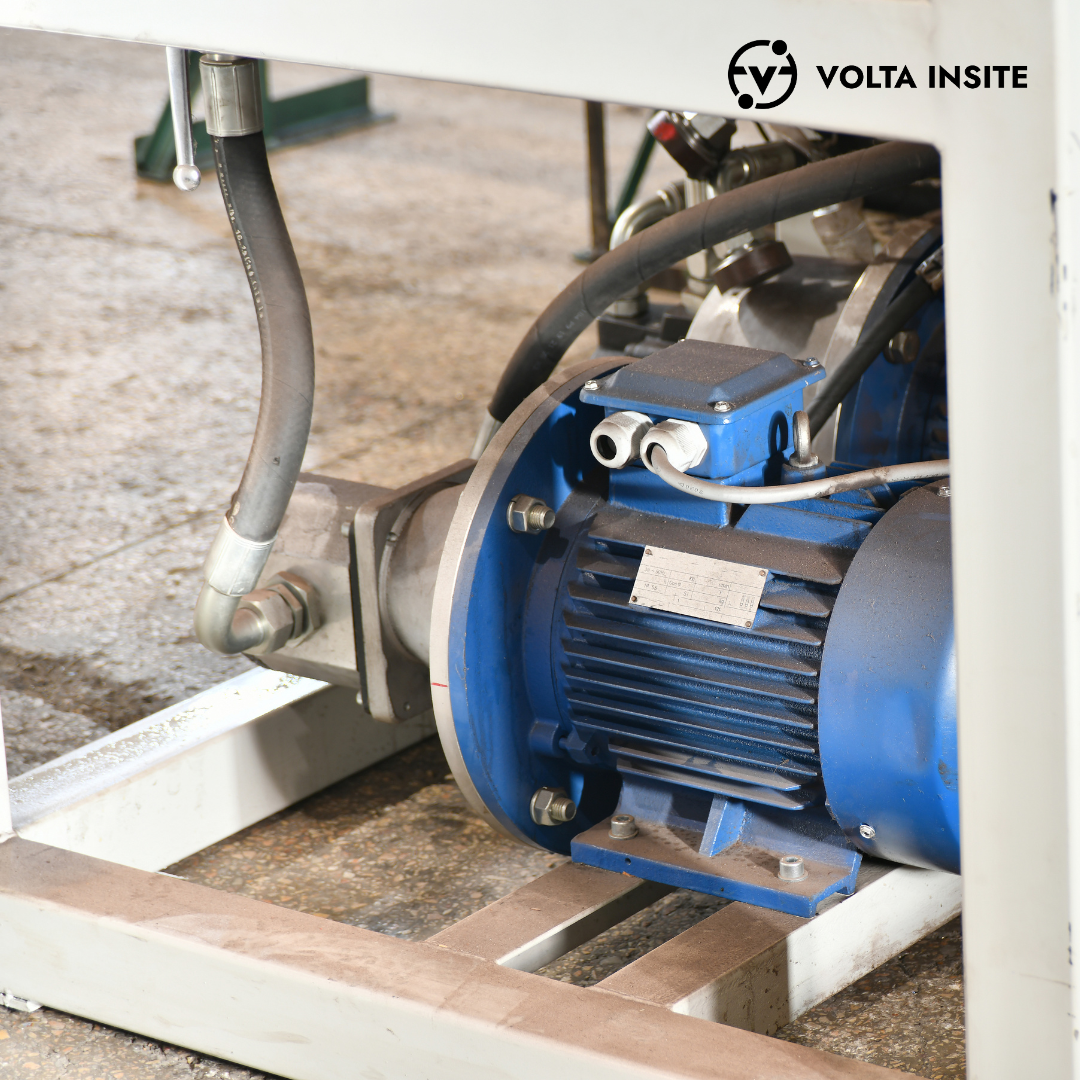

#2: Motor and Drive Optimization

Electric motors are major energy consumers in oil and gas operations, powering pumps, compressors, and fans. Employing variable frequency drives (VFDs) enables precise control of motor speeds, matching output to actual demand and minimizing wasted energy. Regular maintenance and proper motor sizing also ensure maximum efficiency.

#3: Predictive Maintenance Based on Power Quality

Instead of waiting for equipment to fail, predictive maintenance leverages data from power quality monitoring to identify early signs of electrical issues. This proactive approach reduces unplanned downtime and avoids the energy inefficiencies that occur as equipment deteriorates.

#4: Power Factor Correction

Oil and gas facilities often deal with reactive power, which doesn't perform useful work but increases overall power demand. Installing power factor correction devices reduces this waste, lowers utility bills, and improves electrical system performance.

#5: Upgrading to Energy-Efficient Equipment

Investing in modern, energy-efficient pumps, compressors, and lighting systems can yield significant long-term energy savings. Additionally, pairing new equipment with robust energy management helps realize its full efficiency potential.

How Volta Insite Supports Energy Optimization

Volta Insite’s InsiteAI solution is designed for the oil and gas sector’s complex electrical environments. It combines advanced power quality monitoring with AI-powered analytics to continuously assess electrical system health. InsiteAI identifies inefficiencies, detects harmful anomalies like voltage distortions and ground faults, and predicts potential equipment failures well before they impact operations.

With this data-driven insight, facility managers can optimize energy usage, reduce unplanned downtime, and lower overall operational costs. The result is a safer, more reliable, and energy-efficient oil and gas facility.