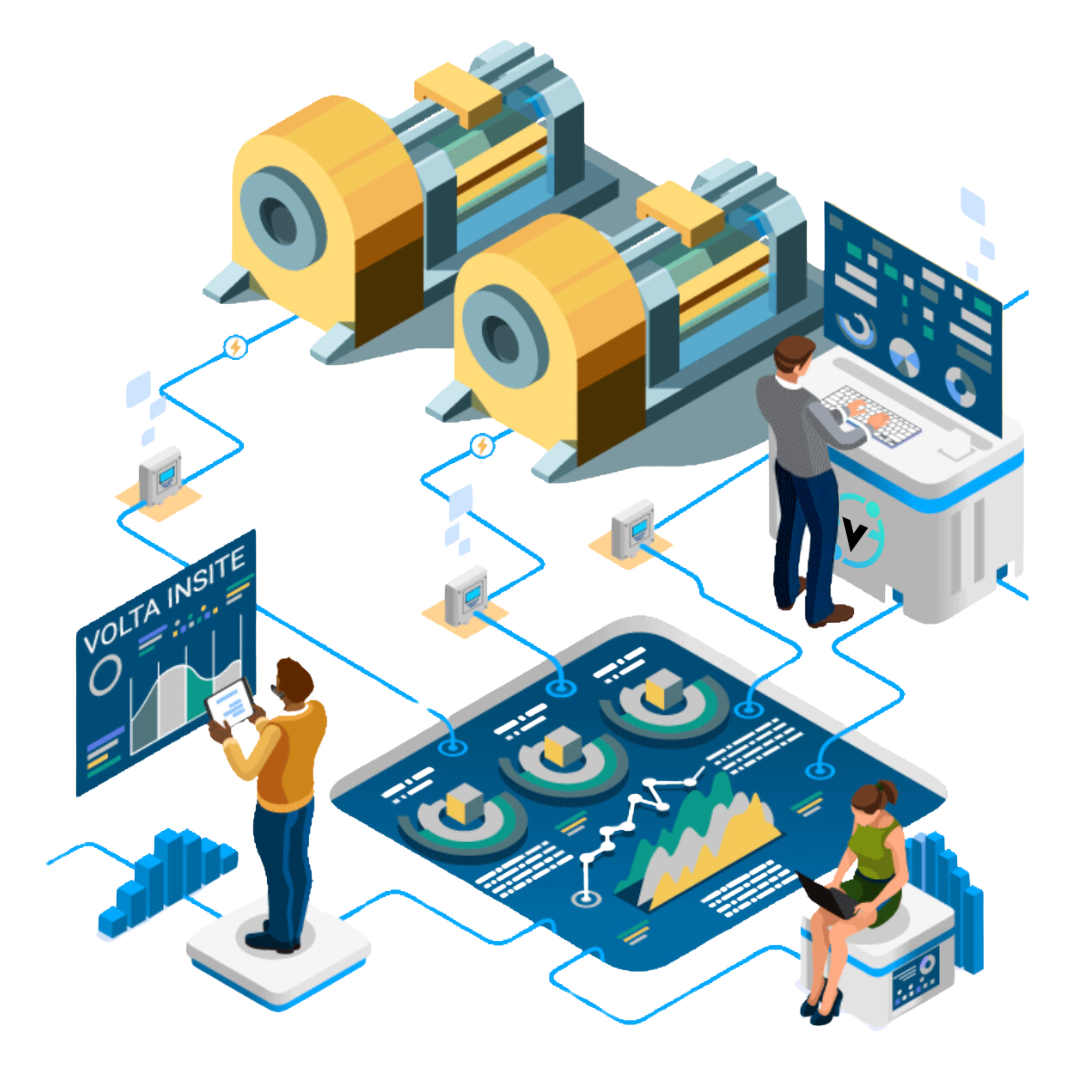

Empowering you with Electrical Data

Volta Insite™ continuously monitors your electrical assets and helps

identify issues before they become a problem.

Book A Call

The Problem

The Hidden Challenges of Electrical Management

Unpredictable Downtimes

Navigating the unpredictability of system failures to maintain continuous operations.

Uncertainty About Power Quality

Addressing the complexities of maintaining consistent power quality in a dynamic electrical landscape.

Lost Operational Hours

Countering the impact of lost productivity due to unexpected power interruptions and failing equipment.

Escalating Maintenance Costs

Tracking the rising costs of upkeep to optimize long-term financial efficiency.

The Solution

Discover InsiteAI: Your Comprehensive Electrical Asset Management Solution

Volta Insite's engineers add context to the data to help our users fully understand the health of their electrical system.

Predictive Maintenance

InsiteAI's advanced algorithms forecast potential issues before they become problems, enabling proactive

interventions.

Prevent downtimes before they even occur.

Learn More About Predictive Maintenance

Power Quality Insights

Our state-of-the-art InsiteAI offers real-time monitoring of power delivery and generation, allowing you to

make

data-driven decisions.

Learn More About Power Quality

- Facility Power Quality

Most power quality issues are not detected by normal plant information systems, but their consequences

include plant

downtime, reduced capacity, production waste, premature equipment failure, and significant financial impact.

- Utility Level Power Quality

“Dirty power” is a term used to describe electricity that deviates from this standard due to spikes, surges,

and dips

and is more commonplace than you would expect. We can pinpoint the anomalies as they happen.

Dedicated Engineering Support

You are not alone, we help you harness the full potential of InsiteAI. Our engineers employ a deep understanding of

electrical systems to ensure you have the data needed to make informed decisions.

Learn More About Our Engineering Support

"Our site saw several current single-phase events. The utility stated it was not on their side, but Volta InsiteAI showed otherwise. This helped prove that the power feed was the culprit and impacting our operations. Since we switched to the new transformer we have not had this issue again."

- J.H.

Applications Engineer

The Features

Continuous Real-Time Monitoring for Your Peace of Mind

InsiteAI provides continuous real-time data and analysis of an electrical asset’s operating condition and efficiency.

portal.voltainsite.com

Charlotte, NC

Power Metering

Node Status:

Cloud Connected

APPARENT POWER

4.96

kVA

UPTIME

1,421

Days

VOLTAGE

548.85

Volts

CURRENT

3.01

Amps

HP

5.98

HP

FREQUENCY

59.99

Hz

Wave Forms

Node Status:

Cloud Connected

S/N: 20052

Data Collection

Our cloud connected sensors are easily installed on your most critical electrical assets.

Data Analysis

Electrical data is then pushed up to the Volta Insite cloud for analysis.

Intelligent Actions

InsiteAI continuously monitors your electrical assets and helps identify issues before they become a problem.

Optimized Maintenance

Once installed our Insite Node provides continuous real time voltage and current readings.

Volta Insite Hardware

There are two major hardware components to the Volta Insite solution that

require installation:

Node 2.0

The Node collects data for calculations and measurements. It sends this

data to the cloud and shares it with the user interface when requested.

It's typically placed in the MCC room but can also be located externally

for easy access during operation.

VI Module 3.0

Each Node comes with a VI-Module which mounts within a cabinet, fused

disconnect, MCC bucket, or other suitable location. The VI-Module has

terminals for connecting current transformers and voltage taps.

Case Study

Real-World Applications of Volta Insite

In a world where operational efficiency is paramount, staying ahead of equipment failures is a game-changer. With InsiteAI's powerful combination of real-time alerts and advanced analytics, businesses now have the tools they need to predict and prevent potential disruptions before they occur.

Client Problem: VFD and Pump operated normally under utility power but would kick off under generator power. Multiple technicians and an electrical contractor recommended to the customer that an expensive power harmonic filter was required to address the problem.

Volta Insite was called in to determine the root cause of the issue and with our data captures and continuous monitoring we were able to document transient events when utility power switched over to back-up generator power. The transient events on power switch-over showed that the voltage from the generator was oscillating significantly. Simply adding a small filter on the sense side of the voltage regulator resulted in the system working correctly and a 20x savings.

Stackpole

Client Problem: 750 Ton Hydraulic Press, Motor and VFD had failed catastrophically twice, at a heavy cost for each incident with multiple days of downtime during a high priority production run.

Volta Insite was called in to asses if the motor rebuild was at fault for the previous failures. As the equipment ran we used our continuous waveform captures to monitor the complete work cycle of the motor. With this data we determined the motor was being overloaded across the full 7 second work cycle, leading to overheating and eventual failure.

The simple solution was to slow the work cycle down to 9 seconds, which resulted in an immediate continuation of production without any additional failures. This allowed the customer to fulfill their contract on time.

The simple solution was to slow the work cycle down to 9 seconds, which resulted in an immediate continuation of production without any additional failures. This allowed the customer to fulfill their contract on time.

Client Problem: During multiple black-out tests there were incidents of motor and VFD failure on air recirculation fans.

Volta Insite was called in by Johnson Controls during the commissioning phase for the new hospital. Concerns arose about transients and over voltage conditions due to the number of harmonic filters in the facility and how they affected the current and voltage of the power distribution system. With our continuous waveform and transient captures, we were able to prove that voltage transients were minimal in nature and not the underlying issue. Volta Insite’s further diagnostics identified the cause of failure was faulty manufacturing on the air recirculation fans.

Our Goal is Zero Unexpected Downtime and Lower Operating Costs for Our Customers.

With Volta Insite’s automated intelligence solution, asset monitoring becomes proactive rather than reactive. By detecting anomalies early on, businesses can address potential issues before they escalate, saving time, money, and ensuring uninterrupted operations.

Book A Call