How HVAC Equipment Failure Impact Commercial Buildings

07/11/2024

07/11/2024

Back to Articles

Back to Articles

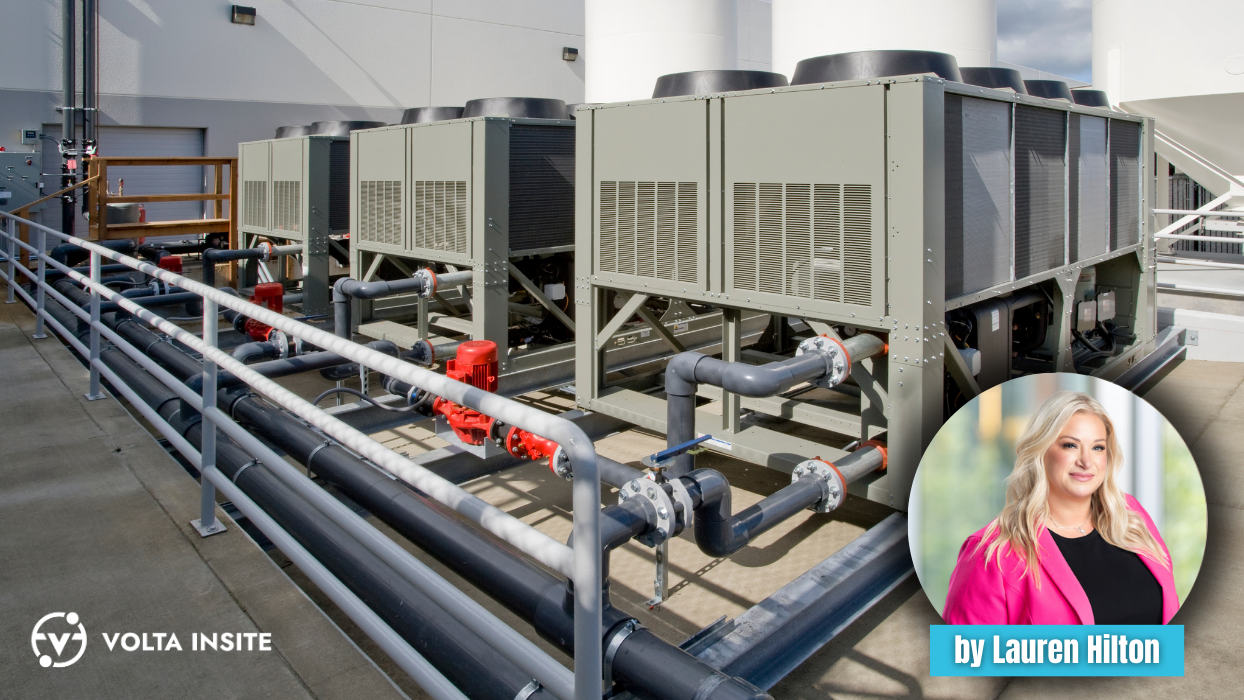

Commercial HVAC systems are essential for maintaining comfort, air quality, and overall operational efficiency in large facilities such as office buildings, hospitals, hotels, and manufacturing plants. These systems operate in demanding conditions, often supporting 24/7 operations, and this can cause them to be more susceptible to untimely breakdowns or a decrease in equipment performance. Equipment failures can be disruptive, costly, and difficult to manage, particularly in facilities where maintaining stable environmental conditions is critical.

Without proper monitoring and manufacturer recommended maintenance, HVAC units can be at a higher risk for failure. This can lead to costly repairs, unplanned downtime, strain on personnel and the potential for lost revenue. Understanding the risks and implementing the right solutions can help facility managers prevent these potential costly incidents and ensure their HVAC systems continue to perform optimally.

The Impact of HVAC Equipment Failure

The failure of HVAC systems in a commercial setting can have a ripple effect on various aspects of a facility's operations. Some of the most common consequences of equipment failure include:

Disrupted Operations

In environments like hospitals, data centers, office buildings and hotels, where maintaining specific temperatures and air quality is crucial, a failure in HVAC systems can lead to major disruptions. If the system goes offline, not only does it impact comfort levels, but it can also interfere with sensitive equipment, such as medical devices or IT systems.

Increased Repair Costs

When HVAC units are not regularly monitored or maintained, small issues can quickly turn into major failures. A system breakdown can result in costly emergency repairs, and if the failure is severe enough, it could lead to the need for complete equipment replacement. These unplanned repair costs can add up and cause strain on operating budgets.

Energy Inefficiency

Malfunctioning HVAC systems often consume more energy as they struggle to meet demand, which can result in skyrocketing utility bills. This inefficiency also places a strain on the building’s power supply, potentially leading to further equipment failures or outages.

Decreased Lifespan

Without proper care, HVAC systems are prone to wear and tear, reducing their operational lifespan. When a system is not properly and regularly maintained, parts such as compressors, motors, and coils are forced to work harder than necessary, which can lead to premature breakdowns and costly replacements. Being able to plan for equipment end-of-life is crucial for budgetary planning.

Compliance and Safety Issues

For certain industries, maintaining a regulated temperature or air quality is more than just a comfort issue—it’s a compliance issue. HVAC failures could lead to non-compliance with industry standards, resulting in fines or other legal repercussions.

Proactive Solutions to Prevent HVAC Failures

To avoid these common issues, facility managers can implement a proactive approach to HVAC maintenance and management. The following strategies can help mitigate the risk of equipment failure:

Routine Inspections and Maintenance

Scheduling regular inspections and maintenance is one of the most effective ways to prevent HVAC failures. Trained technicians can identify early signs of wear and tear or operational inefficiencies before they lead to larger issues. Regularly changing filters and belts, inspecting ductwork, and checking refrigerant levels are basic steps that can keep systems running smoothly.

Energy Monitoring

Monitoring energy usage can help facility managers detect anomalies in how their HVAC systems are operating. A spike in energy consumption could indicate that a unit is struggling to maintain performance, signaling that repairs may be necessary.

Environmental Controls

Keeping track of temperature and humidity levels in large facilities can also provide insights into HVAC performance. If environmental conditions fluctuate unexpectedly, it could point to an issue with the HVAC system that needs to be addressed before failure occurs.

Predictive Maintenance with AI

Traditional maintenance schedules can only go so far in preventing equipment failure. For a more comprehensive approach, predictive maintenance solutions powered by AI, such as Volta Insite’s InsiteAI, offer an advanced way to monitor and maintain HVAC systems. InsiteAI continuously tracks performance metrics and uses predictive analytics to identify potential issues before they become critical failures. By leveraging real-time data, facility managers can address problems early, minimizing downtime and repair costs.

Contact Volta Insite Today!

The risk of HVAC equipment failure in large facilities is a concern for facility managers. By implementing proactive strategies, it’s possible to keep these vital systems operating smoothly. Predictive maintenance powered by AI, like InsiteAI from Volta Insite, offers a cutting-edge solution that can help prevent costly breakdowns, improve system efficiency, and extend the lifespan of HVAC equipment.

For more information on how Volta Insite’s solutions can improve your HVAC performance, contact us today to learn more about our services.